In TRP Division, we produce a wide range of moulded rubber products. Use of technologies ranging from Injection, Transfer, Compression moulding as well as Vacuum moulding to produce top quality product with or without metal bonded, suiting various applications, designs and requirements from customers.

Our moulding equipment are capable to produce precision articles of less than 0.5 grams per piece through injection moulding, up to a flat sheet of 3000mm x 3000mm by compression moulding.

We utilize a wide range of polymers from natural and various types of synthetic rubbers to produce high technical input rubber products. The common range of polymers used are NR, SBR, NBR, CR, EPDM, Silicon, NPVC, Hypalon, HNBR, FKM, IIR and BR. Vulcanization systems by either Sulphur or Peroxide to meet specifications required by customers. Adding to the advantage is KOSSAN’s ability to design and mix compounds to meet these specifications called out in drawing.

Sectors served including Automotive, Aerospace, Fire-fighting and Flow Control, Construction, Mining, Rail and other General applications through contract manufacturing arrangement.

Products manufactured ranges from:

Aircraft Braking Seals

Aircraft Braking Seals

In the Automotive sector, we produce a wide range of rubberised components for the OEM and replacement market through contract manufacturing arrangement. Over the years, KOSSAN has built strong partnering relationship with Tiered 1 manufacturers in supplying to major OEM in the United States, Europe, Australia, and Asia regions. More than 90% of autoparts components produced by KOSSAN are exported through Tiered 1 and 2 partners to major OEM brands in these regions.

Through these partners, KOSSAN has also made its name amongst OEM Car manufacturers and enabling it to further developing its quality systems to higher level meeting OEM standards, thus creating values to our partners and their customers. Recognitions and direct Supplier Evaluation from the OEM enhanced our systems; providing us with inaugural access to OEM platforms and direct supplier performance ratings.

Products Capabilities include:

Jounce Bumper

Damper

Exhaust Hanger

Spring Pads, Isolators & Seats

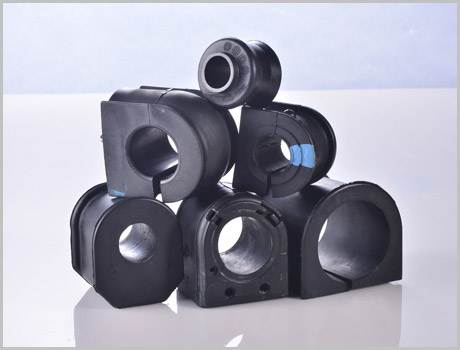

Stabilizer Mounts & Grommets

Suspension Bushings

We manufacture a large range of pipe seals, gaskets and valve seats. Most of our pipe seals have been certified through our clients by international governing bodies such as NSF, FM, WRAS, ACS, DVGW and UL. Applications include pneumatic air-line, sewage, fire-fighting and portable water.

Flow Control Gasket

Valve & Pipe Seal Gaskets

In the Industrial or General sector, KOSSAN also manufactures wide range of products for various industrial applications. We manufacture standard and custom designed industrial rubber products meeting various specifications and standards.

General Moulded Parts

General Moulded Parts

Rubber Sheet

General Moulded Parts

Switchgear Parts

Over the years, Kossan has built its name amongst shoe manufacturers in providing contract manufacturing solution in the production of Rubber Soles for men, women and children shoes. Kossan serves many of the famous brands such as Kangaroo, Bonia, Charles & Keith, Peter Werth, Gucci, Police, Obermain, Heatwave, Frontier, Christy Ng and many more.

We are capable to formulate our material into solid or rubber foam of various colours, to suit customers’ preferences and designs.

Material can be Anti-Slip, Abrasive, Oil Resistance and Electric (ESD) Resistivity for various applications.

Type of Soles produced: